PRODUCT DISPLAY

WELCOME TO INQUIRE

Address: No. 1370, Fenghuang Middle Road, Yisu River, Xiangtan City, Hunan Province

Phone:0731-57881242 0731-57880206

Fax:0731-57880281

Zip code:411228

E-mail:root@centrifugext.com.cn

product details

SS Three-column Manual Bottom Unloading Centrifuge

A motor drives the basket and material is fed into it from its top, distributed evenly onto the walls of the basket. Under the centrifugal force, the liquid phase is discharged through the filter cloth and the holes of the basket wall, and then out of the machine through the tube for discharging liquid, with the solid phase intercepted in the basket and then discharged manually from its top after the machine stops.

category:

Three-column Centrifuge

Contact Us

DESCRIPTION

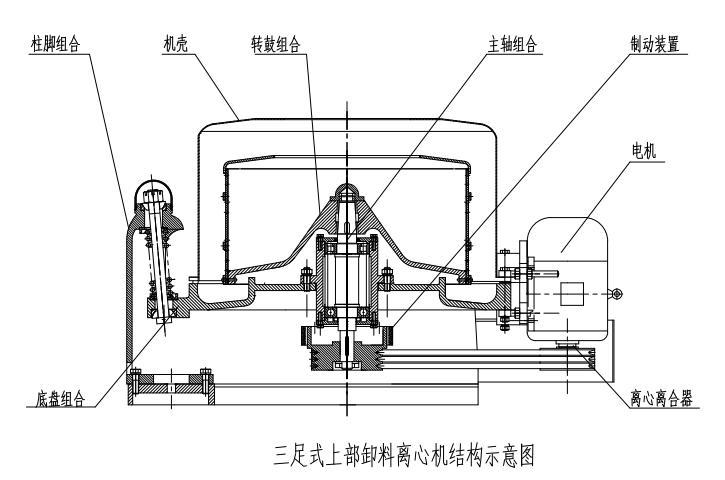

Structures and Principles

A motor drives the basket and material is fed into it from its top, distributed evenly onto the walls of the basket. Under the centrifugal force, the liquid phase is discharged through the filter cloth and the holes of the basket wall, and then out of the machine through the tube for discharging liquid, with the solid phase intercepted in the basket and then discharged manually from its top after the machine stops.

Characteristics and Uses

SS Series are a kind of the three-column top discharge batch-filtering centrifuge. Their structures are simple, so they are easy to operate. All the working procedures can be adjusted according to the requirements, the cake can be sufficiently washed and particles of the solid are not easy to break. Adaptability is another feature. They can be used for separating the suspension with particle size of more than 0.01mm..Solid phase can be divided into powder, granule, crystal and fiber, etc. The machine can also be used to dewater bundles such as yarn and textile goods. They are suitable for chemical industry, light industry, food industry, pharmacy, textile and feather industries.

Types and Specification of Main Products

|

Product name |

SS Three-column Manual Bottom Unloading Centrifuge |

||||

|

Type |

SS600 |

SS800 |

SS1000 |

SS1200 |

SS1500 |

|

Basket Inner Diameter(mm) |

600 |

1600 |

800 |

1000 |

1250 |

|

Effective Capacity(L) |

45/50 |

775 |

100 |

140 |

295 |

|

Max Feeding(kg) |

78/85 |

1050 |

140 |

195 |

410 |

|

Speed(r/min) |

166/1900 |

850 |

1200 |

1000 |

1000 |

|

Separating Factor |

860/1213 |

647 |

645 |

560 |

700 |

|

Motor Power(kw) |

3/4 |

37 |

7.5 |

15 |

22 |

|

External Dimensions(mm) |

1325/1022/820 |

1785/1570/930 |

1995/1600/960 |

2315/1720/1085 |

2840/2110/1100 |

|

Gross Weight(kg) |

600/900 |

1142/1500 |

1500/1800 |

2300 |

3800 |

Notes:

1. The technical parameters provided in the instructions of products are preferable.

2. The customer who asks about products please inform us of the characteristic parameter of material and operate condition.

3. The design and the manufacturing of individuation are available:

-Material: carbon steel, common stainless steel, special stainless steel, titanium alloy, rubber-lined carbon steel and plastic-lined carbon steel can be used for the material of the parts suspension contacts.

-Type of motor: conventional motor, explosion-proof single-speed motor, two-speed motor or electromagnetic speed -adjustable motor.

-Mode of brake: mechanical brake or electrical brake.

-Basket speed: regulated with step change speed-adjustment, electromagnetism speed-adjustment or frequency conversion speed-adjustment.

-Type of cover: open, simple closed or integral-overturned- closed.

-The mode to open the closed cover: with hydraulic cylinder, pneumatic cylinder, electromotion cylinder or mechanical balancer.

- Type of foundation: common foundation or no foundation.

- Designs and manufacturing are supplied according to the standard of GMP.

-Other technical demands may be discussed.

previous page

previous page