APPLICATION INDUSTRY

WELCOME TO INQUIRE

Address: No. 1370, Fenghuang Middle Road, Yisu River, Xiangtan City, Hunan Province

Phone:0731-57881242 0731-57880206

Fax:0731-57880281

Zip code:411228

E-mail:root@centrifugext.com.cn

product details

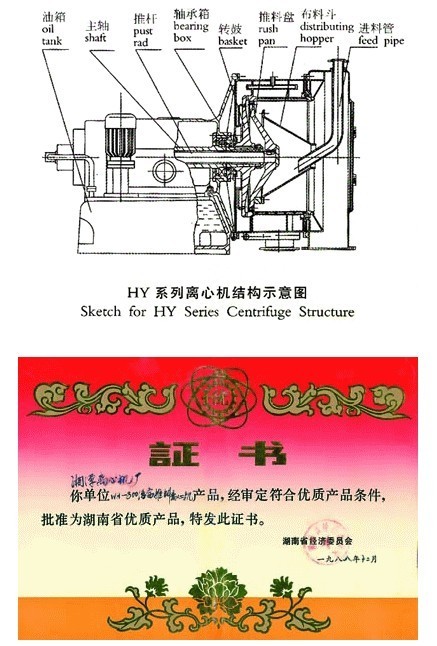

HY Horizontal Piston Pushing Centrifuge

The main motor drives the basket to rotate at a full speed, material being fed into through a feed pipe and distributed evenly on filter screen walls of the basket inner sect. Under the centrifugal force, the liquid is discharged out of the basket through filter screen and the holes of the basket, and then out of the machine through the tube for discharging liquid, while the solid deposits in the basket as a ring layer of cake. As the pusher plate is rotating at the same speed as the basket, it is pushed by the piston to reciprocate continuously and axially, thus pushing the cake layer to move out of the basket and then out of the machine from its front shell base.

category:

Chemical Industry

Contact Us

product details

Structures and Principles

The main motor drives the basket to rotate at a full speed, material being fed into through a feed pipe and distributed evenly on filter screen walls of the basket inner sect. Under the centrifugal force, the liquid is discharged out of the basket through filter screen and the holes of the basket, and then out of the machine through the tube for discharging liquid, while the solid deposits in the basket as a ring layer of cake. As the pusher plate is rotating at the same speed as the basket, it is pushed by the piston to reciprocate continuously and axially, thus pushing the cake layer to move out of the basket and then out of the machine from its front shell base.

Characteristics and Uses

HY Series are a kind of pusher filtering centrifuge with continuous operation. They can perform feeding, separating washing and discharging in sequence at their full-speed running. This machine has the advantages of continuous operation, stable performance, easy operation, large capacity, ideal washing effect and low moisture content of cake. They can be used for separating the suspension with solid phase particle size of more than 0.1mm and with the concentration of over 40%. They are suitable for chemical industry industry, fertilizer, manufacturing salt and alkali, especially suitable for the solid-liquid separation of ammonium bicarbonate, ammonium chloride, mirabilite, etc.

Technical Parameters

| Type | HY800-N | HY1200-N | |

|

Basket |

Diameter(mm) | 800 | 120 |

| Length of Filtering area(mm) | 400 | 500 | |

| Speed (r/min) | 700/800/900 | 500/650 | |

| Separating Factor | 220/287/363 | 170/284 | |

| Max Loading(kg) | 70 | 130 | |

| Length of Pusher(mm) | 40 | 50 | |

| Frequency of Pusher(l/min) | 40 | 30 | |

| Main Motor Power(KW) | 18.5 | 30 | |

| Oil Pump Motor Power(KW) | 11 | 22 | |

| Hydraulic Pressure System Operating Pressure (MPa) | 2.0-3.0 | 2.0-3.0 | |

| External dimensions L × W × H (mm) | 2270 × 1780 × 1400 | 3165 × 2119 × 1912 | |

| Gross Weight(kg) | 4000 | 7700 | |

Notes:

1. The technical parameters provided in the instructions of products are preferable.

2. The customer who asks about products please inform us of the characteristic parameter of material and operate condition

3. The design and manufacturing of individuation are available:

- Material: Common stainless steel, special stainless steel or titanium alloy can be used for the material of the parts suspension contacts.

- Type of motor: conventional type or explosion-proof type single-speed motor.

- Filter screen gap width: 0.1-0.4mm.

- Designs and manufacturing are supplied according to the standard of GMP.

- Other technical demands may be discussed.

previous page

previous page

next page