PRODUCT DISPLAY

WELCOME TO INQUIRE

Address: No. 1370, Fenghuang Middle Road, Yisu River, Xiangtan City, Hunan Province

Phone:0731-57881242 0731-57880206

Fax:0731-57880281

Zip code:411228

E-mail:root@centrifugext.com.cn

product details

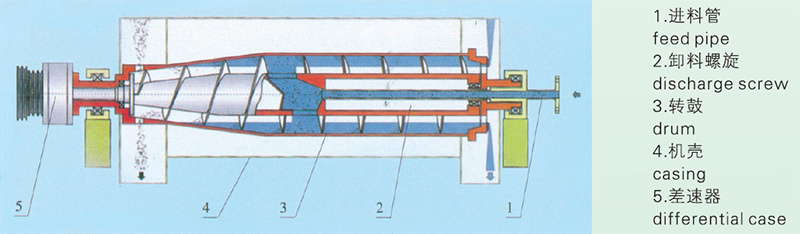

LW Horizontal Spiral Unloading Decanter Centrifuge

Motor drives the solid-bowl without holes and the feeding scroll assembled concentric to rotate together to a higher speed at a certain differential speed. Material is fed into the inner cylinder of the feeding scroll through a feed pipe and into the solid-bowl after the acceleration. Under the centrifugal force, the heavier solid deposits on the solid-bowl wall as a cake layer. The feeding scroll pushes the deposited solid to the conic end of the solid-bowl interruptedly and discharge it out of the solid-bowl and the machine as well through a sludge port, while the lighter liquid forms an inner liquid ring, overflowing out of the solid-bowl through the overflow spout of its big end and discharged out of the machine through drainage.

category:

Spiral Unloading Centrifuge

Contact Us

DESCRIPTION

Structures and Principles

Motor drives the solid-bowl without holes and the feeding scroll assembled concentric to rotate together to a higher speed at a certain differential speed. Material is fed into the inner cylinder of the feeding scroll through a feed pipe and into the solid-bowl after the acceleration. Under the centrifugal force, the heavier solid deposits on the solid-bowl wall as a cake layer. The feeding scroll pushes the deposited solid to the conic end of the solid-bowl interruptedly and discharge it out of the solid-bowl and the machine as well through a sludge port, while the lighter liquid forms an inner liquid ring, overflowing out of the solid-bowl through the overflow spout of its big end and discharged out of the machine through drainage.

Characteristics and Uses

LW Series are a kind of horizontal solid-bowl scroll discharge sedimenting centrifuge. They can be continuously operated and can perform feeding, separating, washing and discharging in sequence at their full-speed running. Their advantages are: compact structure, continuous operation, stable performance, fine adaptability, large capacity and easy maintenance. They are suitable for separating the materials with their solid density larger than their liquid density, that is, the suspension with solid phase particle size of more than 0.005mm and with the concentration of 2-40%. They are suitable for chemical industry industry, light industry, pharmacy and food industry as well as environment protection.

Technical Parameters

| Type |

Basket Inner

Diameter |

Basket Inner

Length of Filtering |

Drum speed (r/min) |

Separating Factor |

Processing capacity M³/h |

Main motor power KW |

Auxiliary motor

power

KW |

Weight (kg) |

Dimensions

L×W×H

(mm) |

| LW245×980-N | 245 | 980 | 5400 | 4000 | 0.5~4 | 7.5~11 | 3 | 1000 | 1898×1200×715 |

| LW380×1140-N | 380 | 1140 | 4000 | 3405 | 3~15 | 22~30 | 无 | 2500 | 2400×1820×1100 |

| LW380×1520-N | 380 | 1520 | 4000 | 3405 | 3~15 | 22~30 | 5.5~7.5 | 2800 | 2745×1570×859 |

| LW450×1092-N | 450 | 1092 | 3800 | 3639 | 6~25 | 30~37 | 无 | 3000 | 2300×2240×1260 |

| LW450×1350-N | 450 | 1350 | 3800 | 3639 | 6~25 | 30~37 | 7.5~11 | 3200 | 2580×1730×1260 |

| LW450×1800-N | 450 | 1800 | 3800 | 3639 | 6~25 | 30~37 | 7.5~11 | 3800 | 3234×1730×1260 |

| LWF450×1458-N | 450 | 1458 | 3800 | 3639 | 6~25 | 30~37 | 7.5~11 | 3500 | 3390×1730×1260 |

| LW520×1560-N | 520 | 1560 | 3500 | 3567 | 10~35 | 37~75 | 11~ 15 | 4100 | 4062×1248×1429 |

| LW520×2080-N | 520 | 2080 | 3500 | 3567 | 10~35 | 37~45 | 11~15 | 5000 | 4537×1248×1429 |

| LW520×2080-NA | 520 | 2080 | 3500 | 3567 | 10~35 | 37~45 | 11~ 15 | 5600 | 4582×1248×1429 |

| LW520×2288-N | 520 | 2288 | 3500 | 3567 | 20~45 | 55~75 | 18.5~22 | 6500 | 4885×1248×1429 |

| LW650×1820-N | 650 | 1820 | 2800 | 2854 | 30~80 | 55~110 | 无 | 7200 | 4200×2280×1500 |

| LW650×2400-N | 650 | 2400 | 2800 | 2854 | 30~80 | 55~90 | 22~37 | 8500 | 4750×2280×1500 |

| LW720×1800-N | 720 | 1800 | 2600 | 2726 | 40~80 | 60~120 | 无 | 9200 | 4304×2915×1473 |

| LW720×2880-N | 720 | 2880 | 2600 | 2726 | 40~80 | 60~120 | 30~45 | 11000 | 5384×2915×1473 |

| LW800×2880-N | 800 | 2880 | 1900 | 1617 | 80~150 | 80~50 | 37~55 | 15000 | 5384×3005×1495 |

| LW1120×2580-N(G) | 1120 | 2580 | 1250 | 980 | 80~180 | 200~225 | 无 | 19000 | 5980×3700×1620 |

previous page

previous page